Global Smart Energy Federation (GSEF)

Newsletter October 2020

COVER STORY

Federal Energy Regulatory Commission (FERC), USA Order No. 2222: A New Day for Distributed Energy Resources

FERC, USA Order No. 2222 will help usher in the electric grid of the future and promote competition in electric markets by removing the barriers preventing distributed energy resources (DERs) from competing on a level playing field in the organized capacity, energy and ancillary services markets run by regional grid operators.

This rule enables DERs to participate alongside traditional resources in the regional organized wholesale markets through aggregations, opening US organized wholesale markets to new sources of energy and grid services. It will help provide a variety of benefits including: lower costs for consumers through enhanced competition, more grid flexibility and resilience, and more innovation within the electric power industry. This rule allows several sources of distributed electricity to aggregate in order to satisfy minimum size and performance requirements that each may not be able to meet individually.

Regional grid operators must revise their tariffs to establish DERs as a category of market participant. These tariffs will allow the aggregators to register their resources under one or more participation models that accommodate(s) the physical and operational characteristics of those resources. Each tariff must set a size requirement for resource aggregations that do not exceed 100 kW.

The tariffs also must address technical considerations such as locational requirements for DER aggregations; distribution factors and bidding parameters; information and data requirements; metering and telemetry requirements; and coordination among the regional grid operator, the DER aggregator, the distribution utility and the relevant retail regulatory authority.

The rule also directs the grid operators to allow DERs that participate in one or more retail programs to participate in its wholesale markets and to provide multiple wholesale services, but to include any appropriate, narrowly designed restrictions necessary to avoid double counting.

The rule does not allow retail regulatory authorities to broadly prohibit DERs from participating in the regional markets. But it does allow retail regulators to continue prohibitions against distributed energy aggregators bidding the demand response of retail customers into the regional markets. The rule also establishes a small utility opt-in. Specifically, it prohibits grid operators from accepting bids from the aggregation of customers of small utilities whose electric output was 4 million megawatt-hours or less in the preceding fiscal year, unless the relevant retail regulatory authority for a small utility allows such participation. The rule explains that state and local authorities remain responsible for the interconnection of individual DERs for the purpose of participating in wholesale markets through a DER aggregation.

When will this rule take effect?

Order No. 2222 takes effect 90 days after publication in the Federal Register (September 17, 2020). Grid operators must make compliance filings to FERC within 270 days of the effective date. Each compliance filing must propose an implementation plan appropriately tailored for its region and must outline how the final rule will be implemented in a timely manner.

Source : https://www.ferc.gov/sites/default/files/2020-09/E-1-facts.pdf

Entries Now Open for ISGAN's 2021 Award of Excellence

♦ 2021 Award Theme: Future-Proofing the Grid Operation via Advanced Digitalisation & IoT

Emerging technologies have the ability to empower smart grid applications and solutions to analyse large data sets, identify patterns, detect anomalies, and make precise predictions based on its learning experience.

The importance of digital is also growing as global energy demand is being reshaped, mainly on renewable energy – such as solar, wind and hydro – and in accordance with the energy conversion policy. Digitalisation is becoming an essential element to stably manage energy demand with an ever more complex energy mix. The recent pandemic situation worldwide has further heightened the importance of digitalisation and the adoption of IoT in grid operation to ensure its uninterrupted operation even under a lockdown environment.

It follows that a rapid response by innovation-based digitalisation will serve as an important variable for companies to gain a competitive advantage. Energy companies should seek to improve efficiency and reduce costs through digitalization and IoT technologies. More importantly, digitalization and IoT technologies will better prepare them to face future pandemic based on their recent experiences. Risk responses such as cybersecurity, information, Data ownership problems, and changes in the working environment are related issues that need to be addressed.

Recognizing the critical importance and the role of smart grids through digitized technologies, we would like to highlight exemplary smart grid projects that enhance the grid stability, balance supply & demand, ensure continuous and reliability of power supply, and enable greater integration of diverse generators. Thus, ISGAN has chosen “Excellence in Smart Grids for Future-Proofing the Grid Operation via Advanced Digitalisation & IoT” as the theme of the 2021 Award of Excellence.

♦ Eligible Projects

- Eligible projects include pilot, demonstration, and deployment projects as well as established programs that that “Future Proofing” the grid operation via advanced digitalization, interconnected grid, data analytics, training programs, grid management systems, and enterprise architecture applied to electric grid operations technology.

- Eligible projects may have any kind of digitized technologies or smart devices developed to help the grid operators to “Future Proofing” its operation including but not limited to understanding and anticipating customer behavior by offering a simple and secure way even under a constrained environment.

The international jury panel will select winning projects based on five key criteria:

-

- Potential impact (25pt)

- Economic rationale (25pt)

- Potential for replication or adaptation (25pt)

- Innovation (15pt)

- Other benefits (10pt)

♦ Timeline of Awards Competition

♦ Submission Deadline: 20 November 2020

Interested parties are encouraged to visit the ISGAN Awards website to learn more about the award rules, entry format, etc.

The winning projects will be recognized next year during the Twelfth Clean Energy Ministerial (CEM12) meeting, which will be attended by the energy ministers and corporate leaders from around the globe.

In addition, the winning projects will be further recognized in ISGAN and GSEF products, proceedings, and events over the ensuing months and promoted to ISGAN and GSEF’s global audience. Moreover, the winners will be offered an opportunity for interviews and exposure via a promotional video that will be publicly distributed via a variety of networks, including ISGAN's official YouTube channel and ISGAN website.

For any further questions, please contact at award@smartgrid.or.kr

GLOBAL STORIES ON SMART GRID

Artificial Intelligence, Blockchain Powered Microgrid Pilots Renewables Trading in Port of Rotterdam, Netherlands

The new microgrid electricity trading platform was jointly developed by S&P Global Platts and Blocklab, the Port of Rotterdam’s blockchain subsidiary. In the two months of operation to date, it has brought both reduced electricity costs and increased renewables use. The platform named Distro draws on both artificial intelligence and blockchain’s distributed ledger technology to enable commercial energy consumers in the port to actively trade renewable energy derived from solar and battery storage to manage their power consumption. The trial, claimed to be the world’s first high-frequency decentralised energy market, commenced in August 2020 in the Port of Rotterdam’s Innovation Dock. The platform provides every market participant with an AI enabled ‘energy trading agent’ software tool that learns their energy needs, preferences and behaviours. The trial provided the participating buyers and sellers with a 48 hour forward market with access to dynamic local energy prices reflecting the supply and demand balances. With the technology, the energy consumers reduced their costs by 11%, while the renewable producers saw a 14% improvement in their revenues. The trial also demonstrated 92% consumption of on-site solar generation, overcoming historic wastages, and a 20% increase in battery storage return on investment.

Read more: https://bit.ly/2SsqH26

Ørsted and Yara Develop Green Ammonia Project in Netherlands

Ørsted and Yara have joined forces in developing a pioneering project, aiming to replace fossil hydrogen with renewable hydrogen in the production of ammonia. The plan has the potential to abate more than 100,000 tonnes of CO2, equivalent to taking 50,000 conventional cars off the road. The two companies will develop a 100 MW wind–powered electrolyser plant for renewable hydrogen production. Their aim is to replace fossil–based hydrogen with renewable hydrogen for ammonia production in Yara's Sluiskil plant, located in the Dutch province of Zeeland.

The renewable hydrogen would generate around 75,000 tonnes of green ammonia (approximately 10% capacity of one of the ammonia plants in Sluiskil) based on dedicated renewable energy supply from Ørsted's offshore wind farms. Ørsted is about to inaugurate its Borssele 1 & 2 offshore wind farm, the second biggest in the world, located off the coast of Zeeland close to the Sluiskil plant. The green ammonia is intended to be used in the production of carbon neutral fertilizer products, decarbonising the food value chain. It also has potential as a future climate neutral shipping fuel.

With its abundant offshore wind resources and large hydrogen consumption centres in coastal areas, the Netherlands are well-positioned to lead the way in green transformation of heavy industry powered by offshore wind. In addition to securing the competitiveness of key industrial sectors and creating economic activity and jobs, this project can be a milestone on the hydrogen roadmap of the Smart Delta Resources cluster in Zeeland, and an important step in the scaling of renewable hydrogen in the Netherlands towards 3 – 4 GW by 2030.

Read more: https://bit.ly/2Sxdepx

Australian Gold Mine Goes 50% Renewable-Powered with Addition of Battery Storage

A lithium-ion battery energy storage system (BESS) supplied by French manufacturer and system integrator Saft has enabled a gold mine in Australia to meet more than 50% of its energy demand with renewable energy. Power station operating company EDL has implemented what is already thought to be Australia’s biggest microgrid operating on hybrid renewable sources - combining wind and solar - along with gas/diesel engines for backup. The system has a combined capacity of 56MW including 13MW of battery storage and is at Agnew Gold Mine, Western Australia, owned and operated by mining company Gold Fields.

The 13 MW / 4 MWh battery storage system, based on six containerized Saft Intensium Max+ 20M megawatt-scale battery storage units allows EDL’s microgrid to integrate variable renewable energy including 4MW of solar and 18MW of wind while maintaining power quality. It is also thought to be the first Australian mine microgrid to incorporate wind power. It also uses a 21 MW thermal power engine.

Read more: https://bit.ly/2Z2CCY6

California Targets Nearly $400M to Fill Gaps in EV Charging Infrastructure

Key Highlights: CEC’s clean transportation plan will direct $133 million for light-duty EV charging systems, and another $130 million for infrastructure for zero-emissions medium and heavy-duty vehicles.

The California Energy Commission (CEC) is putting a “down-payment” of $384 million over the next three years on the electric vehicle charging and zero-emissions vehicle infrastructure needed to meet Gov. Gavin Newsom’s pledge to end sales of new gasoline powered cars by 2035. CEC’s clean transportation plan will direct $133 million for light-duty EV charging systems, and another $130 million for infrastructure for zero-emissions medium and heavy-duty vehicles, most of its electric charging. Another $70 million will go toward hydrogen refueling infrastructure, and $25 million for “zero-and near-zero carbon fuel production and supply,” to meet the need for alternatives to battery-powered vehicles in the decades to come.

Read More: https://bit.ly/37eQ2VY

LG CNS to Lead Smart City Development in Sejong

Key Highlights: The total cost of the project scheduled to be completed in April 2023 is 2.5 trillion.

The Ministry of Land, Infrastructure and Transport and the Korea Land and Housing Corp. announced on October 8, 2020 that the Sejong O1 consortium led by LG CNS has been selected as the preferred bidder for the Sejong smart city project. The project is to build a smart city in a 2.74 million square meter area in Hapgang-ri, Sejong City. The total cost of the project scheduled to be completed in April 2023 is 2.5 trillion. The city is expected to come with smart IT services such as autonomous driving, telemedicine, smart education, drone-based delivery and smart traffic light control.

Read More: https://bit.ly/37exHs4

Hitachi ABB Power Grids Launches Transformer Digitalization Ecosystem

Hitachi ABB Power Grids is launching the TXpert Ecosystem for the digitalization of transformers. The ecosystem is designed to drive data-driven intelligence and decision making in the operations and maintenance of transformers and power grids. It is a complete suite of products, software, services, and solutions that work together and have the capability to integrate with new and existing digital equipment from other manufacturers. Using TXpert Ecosystem solutions for digital asset management of bushings, the real-time status of the bushing health can be monitored and corrective action taken before failure probability becomes high. At the heart of the ecosystem is the TXpert Hub from Hitachi ABB Power Grids – a data monitoring and diagnostics device that also provides connectivity.

Read More: https://bit.ly/3lT5QS3

UK Energy Company Develops First-of-its-kind EV Charging Technology System

Key Highlights: ZPN Energy’s new energy network technology is the first of its kind using the new Open Charge Point Protocol (OCPP 2.0.1), which paves the way for universal contactless charge points for all-electric vehicles.

Coventry-based energy tech company ZPN Energy has become the first business to develop technology using the new standard for electric charging infrastructure. ZPN Energy’s new energy network technology is the first of its kind using the new Open Charge Point Protocol (OCPP 2.0.1), which paves the way for universal contactless charge points for all electric vehicles. OCPP 2.0.1 also enables a number of other benefits, including integration of renewable technology, payment processing and better security and device control. The company’s smart technology can also be used in commercial or domestic property, utilizing green energy tariffs to store and use energy at the optimum levels.

Read More: https://bit.ly/352mO9S

Germany looks to Blockchain to help Decentralize their Energy Economy

The Deutsche Energie-Agentur, also known as DENA, the main governmental group responsible for energy innovation in Germany is looking to move its energy ecosystem to a decentralized database. Working with over 20 other crypto and blockchain entities, Energy Web will build a distributed energy resource database for Germany at the request of DENA. Germany’s energy innovation wing, combined with Energy Web and numerous blockchain and crypto companies, essentially want to digitize the country’s energy system by storing necessary components on a decentralized database.

Built for the next generation of energy ecosystems, Energy Web’s open-source blockchain-based decentralized operating system, called EW-DOS, holds as a key component of the new decentralized database’s test model. The project, however, plans to utilize multiple blockchains, and include technology from KILT Protocol and Parity Substrate — which come from BOTLabs and Parity Technologies respectively.

Read more: https://bit.ly/3dwmLqJ

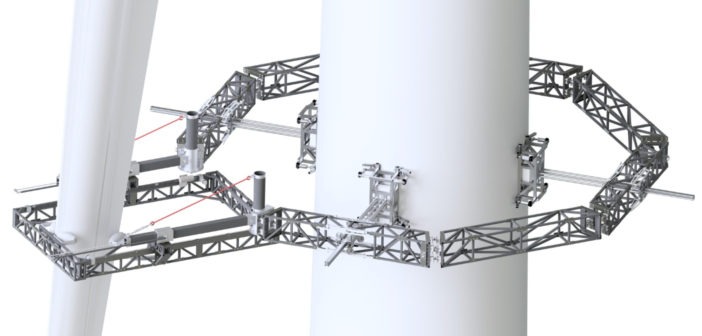

World-first Robotics Technology being developed for Wind Turbine Maintenance

British consortium is pioneering new technology to boost the maintenance capabilities of the industry coinciding with British Prime Minister Boris Johnson’s recent announcement of plans for offshore wind to power every home in the country by 2030

A lightweight robot capable of carrying out an X-ray maintenance survey of wind turbines - offshore and onshore - is being developed to help make the wind power industry operate more efficiently in Britain. Forth Engineering, in Cumbria, together with a consortium of industrial and academic partners - Innvotek, TWI, ORE Catapult, Renewable Advice and London South Bank University - are developing the RADBLAD technology, which should be able to complete a full X-ray survey of a Vestas V47 size turbine and all its blades in just a few hours. The businesses and organisations involved have a wide range of expertise in robotic development and manufacture, radiography development, and AI algorithm software development. The innovation is in line with the UK government’s policy of increasing renewable power to bring all greenhouse gas emissions to net zero by 2050.

There has already been a significant growth in installed wind power capacity within the last decade, especially in offshore wind power in the UK which is the world’s sixth largest producer of wind power. This growth has also meant a higher level of maintenance required across the industry with more wind turbines and more blades needing to be checked for faults.At the moment one of the ways surveys are carried out is manually by maintenance engineers climbing the wind turbine and its blades with rope access.

Read more: https://bit.ly/2T2Ekp4

Russia’s State Atomic Energy Corporation, Rosatom launches Lithium Battery Storage business unit

Nuclear technology company Rosatom, Russia’s biggest electricity provider and the country’s supplier of nuclear fuel for power plants, has opened an energy storage business unit based around lithium-ion batteries. The state corporation - State Atomic Energy Corporation Rosatom to give it its full name - said last week that it has completed incorporation of the energy storage business development arm, to be called RENERA. RENERA was previously Cathode Materials LLC, an enterprise company launched by Rosatom’s nuclear fuel cycle company TVEL. Rosatom said the new unit will develop and trade module type lithium-ion traction batteries. In addition to electric vehicle (EV) industry segments, the company will focus on energy storage systems for applications including emergency power supply, renewable energy and smoothing load demand on the grid.

Rosatom called lithium-ion batteries one of the most cost-efficient and technologically advanced solutions for intralogistics, as well as describing lithium-ion traction batteries as explosion-proof, environmentally-friendly and said that the modules are sealed and do not require maintenance.

Read more: https://bit.ly/376Pp0m

MEMBER UPDATES

Christian Buchel re- appointed as the E.DSO Chair for a New Two-Year Term

European Distribution System Operators (E.DSO) Board of Directors re-elected Christian Buchel as E.DSO Chair for another two-year term on the 15th of October 2020. Five Vice-Chairs of the E.DSO Association have also been reappointed or appointed for the next two years: João Torres, Armando Martínez Martínez, Joachim Schneider, Franz Strempfl and Mindaugas Keizeris.

It is an honour and privilege for me to continue my journey as chair of E.DSO, an Association that in just a decade has become an impressive force and community of leading the DSO companies in Europe said Christian Buchel. Buchel further quoted 'I affirm my strongest commitment to continue our intensive work together with European Colleagues in the usual trustful, open and transparent way.' Christian Buchel whose carrier has spanned the entire value chain of the electricity industry is a member of the management board and director for clients and territories and Europe at Enedis. He previously served the association as Vice-Chair and has been E.DSO Chair since 2017.

Framework Of Future Co-Operation Memorandum Of Understanding Global Smart Energy Federation And Association Of Power Utilities Of Africa

APUA is the Association of Power Utilities of Africa, formerly known as UPDEA (Union of Producers, Conveyors and Distributors of Electrical Energy in Africa) formed of 56 member utilities within 46 counties in Africa. It was established in the year 1970 with headquarters in Abidjan, Côte d’Ivoire. APUA is a non-profit, non-governmental continental organization. APUA is a Member of AFREC Executive Council and Permanent Member of the Council and Management Committee of AFSEC (African Electro-technical Standardization Commission). APUA’s vision (adopted at the Durban Congress in June 2002) is to be the “main catalyst for the realization of access to electricity for all the peoples of Africa”.

In 2012, APUA adopted a mission which is "to bring together African electricity companies and stakeholders in order to make electric energy more accessible, affordable and reliable for African populations”.

The overall objective of the MOU is to launch the creation of a long-term partnership between APUA and GSEF, with the view to develop and implement cooperation programs between members.

The main objective of the APUA and GSEF partnership is to Improve the Development of Smart Grids of African Power Sector.

Specific synergies have been identified in the following areas:

- Conducting studies to identify grid, mini-grid and off grid solutions to provide affordable and reliable energy access.

- Exchange experiences in the data collection, processing, database management and dissemination mechanism to facilitate policy and strategic planning in order to develop smart grids implementation projects

- Organize interregional congress and seminars in issues relevant for their members

- Cooperate in the capacity building and the training of human resources, particularly in virtual training and other e-learning programs.

- Jointly identify opportunities in respective regions which offer the potential to meet the three sustainable energy goals faster and at lower costs.

- Jointly assist electric utilities in Africa to formulate smart grid roadmaps that could guide them in systematic and phase-wise grid modernization to enhance energy access and integration of renewable energy resources and electric vehicles.

The MOU will be signed during the next APUA congress to be held in June 2021 in Dakar Sénégal. The implementation of specific programs and projects under the MOU will be developed through Annual Work Plans. The first work plan will start in 2021.

Article By: Marc Boillot Ambassador for Europe and Africa (Francophone), GSEF.

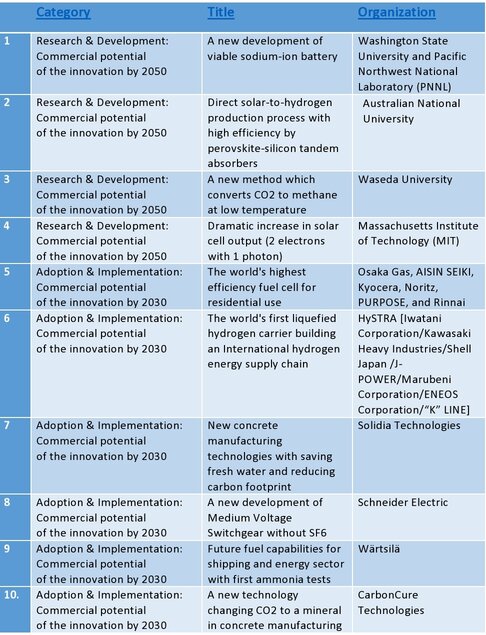

ICEF-Top 10 Innovations

About

Innovation for Cool Earth Forum's "Top 10 Innovations" is an event to select the most notable among recent innovative developments in energy and climate change mitigation. By examining the field "Top 10 Innovations" will provide the latest snapshot of technology development and diffusion with the potential to transform society in the fields of energy and environment. The event helps us to understand the state and trends of innovations in each respective area, and helps find areas where further efforts are needed in the future.

ICEF 2020 WINNERS

Electromobility in Grids: Interview with Marc Petit

Marc Petit, Professor at Centrale Supélec and member of the Scientific Council of Think Smartgrids, is the lead author of the Global Smart Energy Federation (GSEF) report "Electromobility in Smart grids: State of the Art and Challenging Issues ". In the report, Prof Petit discussed the challenges of electromobility in France and around the world.

Where does France stand today on these issues of Electromobility and their integration into electricity grids?

Today, the active integration of electric vehicles into electric grids (notably through the use of their batteries) is no longer just a subject for laboratory or experimentation: these are technologies that are developing rapidly. France is contributing to this development, with stakeholders in electric networks and mobility present in France and abroad. These include PSA, Renault, Bouygues Energies & Services, Siemens, EDF and Engie, as well as collaborations with Enedis, such as the aVEnir project. The French Energy Regulatory Commission is also interested in the subject: it published in 2018 a report giving guidelines for electric mobility integration, some of which are intended to facilitate the connection of two-way terminals that would allow power to be injected from electric vehicles into the grid. Thus, we can see that the French sector is dynamic on these subjects, which no longer only brings together academic laboratories and startups, but also major players in the field.

What is the situation in other countries?

Some countries are currently in more advanced stages. This is the case of the United States, which is doing a lot of experimentation, with different types of fleets such as electric buses. We can talk about the NUVVE company, specialized in vehicle-to-grid (V2G), which is currently carrying out projects in Europe, notably through the creation of DREEV with EDF.

What are the challenges for players in the French ecosystem?

We can consider three of them. First, the problem of standardization. Secondly, we still need to define appropriate regulations to allow power to be injected into the network from electric vehicles. Finally, there is the problem of finding a good business model that will make equipment or infrastructure costs profitable: the organization of markets and network services must be compatible with V2G equipment and vehicles. More generally, this involves making the most of flexibility in electrical systems. These are issues that the players in the sector need to work on.

GBCI Announces New Safety First Pilot Credits for PEER Rating System in Response to COVID-19 Pandemic

Today, Green Business Certification Inc. (GBCI), the premier organization independently recognizing excellence in green business industry performance and practice globally, announced the release of Safety First Pilot Credits for its PEER rating system in response to the COVID-19 pandemic.

PEER (Performance Excellence in Electricity Renewal) promotes best practices and establishes performance measures that enhances power system performance to make it more reliable, resilient and efficient. To ensure that the electrical systems are operated safely during re-occupancy or restarting of equipment post-pandemic, PEER has introduced the Safety First Pilot credits for all cities, utilities, campuses, and transit projects.

PEER pilot credits are a group of credits which are designed to test new innovative strategies that bring out sustainable power system design and/or facilitate introduction of new credits to PEER. These credits are not part of the current version of the rating system and can be used in the PEER Innovation credit category. These credits are awarded based on project teams attempting and achieving the credit requirements. The credits may change as feedback is received.

PEER Safety First Pilot Credit 1: Electrical System Operations, Management and Safety (for Cities and Utilities, and Campuses)

There’s a lot of uncertainty, on restarting operations during the ongoing phase and post-COVID work environment. In this regard, Cities, Utilities, and Campuses are looking for guidance on how to restart their operations and how to reduce their impact due to COVID-19.

It is the need of the hour to implement safety procedures as listed in the PEER’s safety first pilot credit 1 on re-starting the power system and other electrical equipments with special focus on the health and hygiene measures, more than ever.

PEER Safety First Pilot Credit 2: Electrical System Operations, Management and Safety (for Transit)

With the easing of COVID-19 restrictions, some governments throughout the world have planned or planning to reopen public transport systems as people would return to work, school, and other leisure activities. Still, many cities are struggling with the safe operation of transit systems and also, passengers seem reluctant to travel in masses.

PEER’s safety first pilot credit 2 provides guidance on the strategy and measures that transit operators should implement to prevent the spread of COVID-19 both in trains and stations, and also lists the safety procedures that transit projects should follow, especially in recommissioning any electrical system post pandemic, in order to prevent damage to electrical equipments.

PEER Safety First Pilot Credit 3: Accelerate Digital Transformation (for Cities and Utilities, and Campuses)

As we navigate from current work environment towards a remote way of working, we want to help all employees to be:

- Safe & Healthy, and

- Digitally Prepared

So, projects can leverage digital technologies which are capable to deliver decisive advances in customer experience, and operational efficiency across power system operations. Digital transformation should drive positive outcomes for all project types which will enhance the power system performance.

PEER’s safety first pilot credit 3 promotes best digital practices that reduce manual operations and enhance data driven control and optimization of electrical equipments, as intelligence and meaningful data availability have historically been key factors in bringing about paradigm shifts, and there is vast promise in what digitalization can bring to the power ecosystem.

The requirements outlined in these Pilot credits are some of the best practices that facilities should consider implementing at any time (not restricted to episodic events such as the COVID-19 pandemic) for safe operation of electrical equipments and to promote health and safety of their personnel. Please see the Pilot Credit Language in the PEER Resources page for more details on the requirements.

Contact us at peer@gbci.org with any questions on these pilot credits.

GSEF SMART GRID EDITORIAL

Recycling Solar PV Panels

Ashes to Ashes, Dust to Dust. A very proverbial saying, but this rarely applies to materials we extract from earth. Silicon-dioxide (silica/quartz/sand) used in semiconductors, inverters and other industries are often not recycled. Solar photovoltaic (PV) panels are also made from such silicon wafers sandwiched between a glass and plastic back sheet (with tin, lead and silver connections) duly held by an aluminum frame. A small copper wired junction box sits underneath. Due to its falling cost and ease of installation, solar PV now proliferates the globe but they are also on the verge of creating their own e-waste problem. Right now, the world does not have a cost-effective plan to deal with solar PV panels after their useful life.

The International Renewable Energy Agency (IRENA) projects that by 2050, about 78 million metric tons of solar panels will see their end of useful life and generating thereafter about 6 million tons of PV e-waste annually. The initial solar PV installation (of early 2000) is now approaching its end of useful life. While this may be a small amount today, but going forward this waste volume will increase exponentially with each passing decade (commensurate with increasing deployment). There are arguments being made that the PV e-waste is (and will be) a small fraction of the cumulative total solar PV panels manufactured/installed and an even smaller percentage relative to the total electronic e-waste. But a counter argument would be that this is still substantial and points to a growing e-waste problem. Add to this the panels that get damaged due to storms and future replacements with more efficient panels, and this number will progressively grow faster. If nothing is done to recycle it, most of these PV panels will go to landfill.

In a recent article for the WIRED (www.wired.com) that originally appeared on Grist (www.grist.org), written by Maddie Stone, titled “Solar Panels are Starting to Die, Leaving Behind Toxic Trash”, a good insight is presented on the current state of the PV recycling industry (or lack thereof). While several countries in EU have mandated such recycling efforts, most other countries including the United States, India and China have no such national initiatives. The article points to a recovered value of $3 per PV panel recycled against a recycling cost of $12-$25 (including transportation) in the USA, while land-filling just costs about $1 per panel. Another reference in the article states that the “recovery cost far exceeds the recycling revenue by almost 10-1 ratio”. The article concludes that better attempts/efforts should be made to use modern processes to achieve 95% of recapture and prevent these old PV panels from going to landfill. If 95% of the semiconductor material can be recovered and put back in the new PV panel (and repeated), the original silicon material could stay in a productive PV use lasting 1,200 years.

Arup, a global organization (www.arup.com ) recently published a white paper titled “Circular Photovoltaics – Business Models for Australia’s PV industry”, where the issues of PV e-waste is examined in detail and recommendations made. While the data analyzed is for Australia, it has several relevant learnings for the global market. Gleanings from this report include (1) Australia’s PV e-waste could reach between 300,000 to 450,000 tons by 2040; (2) it needs to establish an extended producer responsibility to address end of life; (3) standardized panel designs with a view towards recycling is needed; and (4) development of a circular economy strategy. The paper further adds that the potential recycle value of typical panel is almost “inverse” of its composition elements by weight. For example, PV panel glass is 70% by weight but recycle value is 8% of the total panel. Similarly, the aluminum frame is 18% by weight (26% recycle value). Silver which is a mere 0.06% by weight, has a recycle value of 47%, while the silicon cell at 3.65% has a value of 11%.

First Solar (a PV global giant) states that it has initiated efforts to recycle their own PV panels in the USA, Germany and Malaysia, using custom technology to disassemble/recycle their old panels, thereby recovering 90% of the materials. Other global examples of third-party PV recycling efforts include Veolia/France and SMaRT Center at the University of New South Wales/Australia. The SmaRT@UNSW recycling process is unique and attempts to eliminate unnecessary transportation costs (to central recycling depots), by creating affordable distributed “micro-factories” near consumption points (hence convenient and accessible).

In a recent “World Solar Technology Summit” attended online by over 26,000 from 149 countries, presented its vision as to how the solar e-waste crises could be solved. Its rationale lay in not only cheaper cell manufacturing but a more sustainable technology that would achieve the following:

- Breakthrough processes that would see the current 45% wastage in silicon cell production to just 5%

- Process improvement towards a higher “champion efficiency” rather than today’s “average efficiency”

- New cell technologies leading to better longevity with no loss of efficiency (resulting in a lower LCOE)

- Breakthroughs in perovskite solar cells (PSC) that will need less cell materials for the same power output

Notwithstanding all of the above, I think we are at the same crossroads (as many other industries before) that had similar viewpoints on end-of-life (i.e. computers, cellphones, packaging, appliances) but nothing substantial has happened in its recycling. Except for EU where some appliances are “returned” to the manufacturer after their end-of-life, most countries still have no mandated recycling strategy. With no policy intervention, this problem has been left to viable market forces that may emerge at some point in the future. Till then, it is land-fill.

I think the question for the PV industry, is not just focusing on the business model of driving production costs lower, but rather if better business models could make the PV technology have a higher “terminal value” at end-of-life, by either prolonging field life and/or allowing for a re-purposed useful-life. It is possible to work along these lines with mandated country policies to reduce ever-increasing e-waste. A few thoughts below:

- Standardize panel designs towards a view to easier recycling. For example, currently the glass (70%) tends to “contaminate” the recycling efforts with “impure crushed glass”.

- Promote PV panel lease rather than sale. This adds producer responsibility. Such a step will allow manufacturers to build better panels (albeit at a higher cost) but yielding better long-term benefits such as (a) longer useful life beyond 25 years; (b) better weather-resistant designs; and (c) a better opportunity to redirect older products to other projects.

- Offering high-ambient temperature rated PV panels. Most PV panels today are deployed in hot tropical climates (40-deg C ambient) and this is a growth segment. Derating panels from the 25 deg C standard test data often leads to erroneous design application and hence premature field failures.

With no policy intervention, the PV e-waste will add to the existing cell-phone/PC e-waste heap (likely followed by lithium-battery e-waste).

Article by Ravi Seethapathy, GSEF Ambassador, Americas

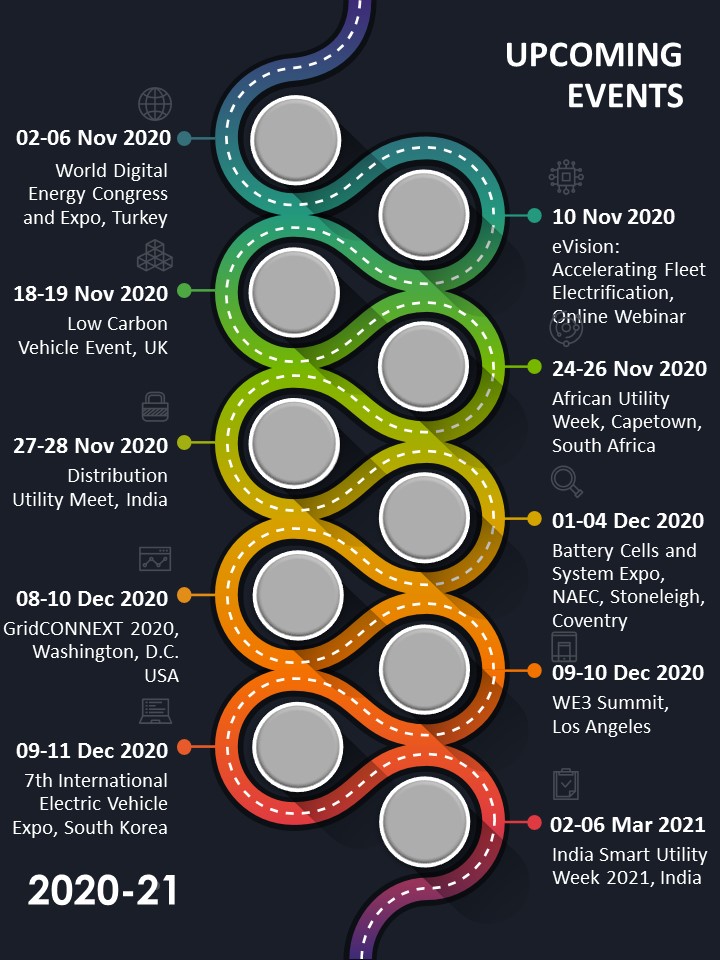

Upcoming Smart Grid Events

INTERNATIONAL EVENTS

E-Newsletter October 2020

Content

- Federal Energy Regulatory Commission (FERC), USA Order No. 2222: A New Day for Distributed Energy Resources

- Entries Now Open for ISGAN's 2021 Award of Excellence

- Artificial Intelligence, Blockchain Powered Microgrid Pilots Renewables Trading in Port of Rotterdam, Netherlands

- Ørsted and Yara Develop Green Ammonia Project in Netherlands

- Australian Gold Mine Goes 50% Renewable-Powered with Addition of Battery Storage

- California Targets Nearly $400M to Fill Gaps in EV Charging Infrastructure

- LG CNS to Lead Smart City Development in Sejong

- Hitachi ABB Power Grids Launches Transformer Digitalization Ecosystem

- UK Energy Company Develops First-of-its-kind EV Charging Technology System

- Germany looks to Blockchain to help Decentralize their Energy Economy

- World-first Robotics Technology being developed for Wind Turbine Maintenance

- Russia’s State Atomic Energy Corporation, Rosatom launches Lithium Battery Storage business unit

- Christian Buchel re- appointed as the E.DSO Chair for a New Two-Year Term

- Framework Of Future Co-Operation Memorandum Of Understanding Global Smart Energy Federation And Association Of Power Utilities Of Africa

- ICEF-Top 10 Innovations

- Electromobility in Grids: Interview with Marc Petit

- GBCI Announces New Safety First Pilot Credits for PEER Rating System in Response to COVID-19 Pandemic

- Recycling Solar PV Panels

- INTERNATIONAL EVENTS